When we think of data analytics, it’s easy to simply think of suits examining market trends and trying to see how they can milk customers for more money. However, there is a lot more to it than that; companies like Google and Facebook have made themselves giants by the way they collect, analyze, and use data.

The relevance of data is not related to IT companies, however; companies and businesses that use the logistics marketplace are also in a position to benefit significantly from data analytics. It allows for greater supply chain visibility, flexibility, and resilience. The challenge lies in making sure data is being correctly identified, prioritized, and acted on; tracking the wrong data, simply not having enough of it, or misinterpreting it will cause your business to lose out on the ability for data to solve complex challenges and make your operations as efficient as they can be.

What we will do below is look at some of the supply chain challenges data analytics seeks to solve.

Labor

Good talent is becoming harder to find; making sure you have the skilled labor you need may be one role of data you may not have considered.

One of the things that supply chain data can provide is a deeper understanding of employee turnover. Data will enable you to study the cost of turnover per associate, which can go up to $4,000, and discover what it is that causes turnover at both a micro and macro level. You can use this data to make informed decisions of predict the effects of certain changes you may be intending to make.

Peak Supply Chain Planning

Very often, you will feel like no matter how much you predict and prepare for peak demand, it isn’t enough. When the demand hits, our confidence crumbles and we’re back to firefighting, moving products from reserve to active area as and when needed.

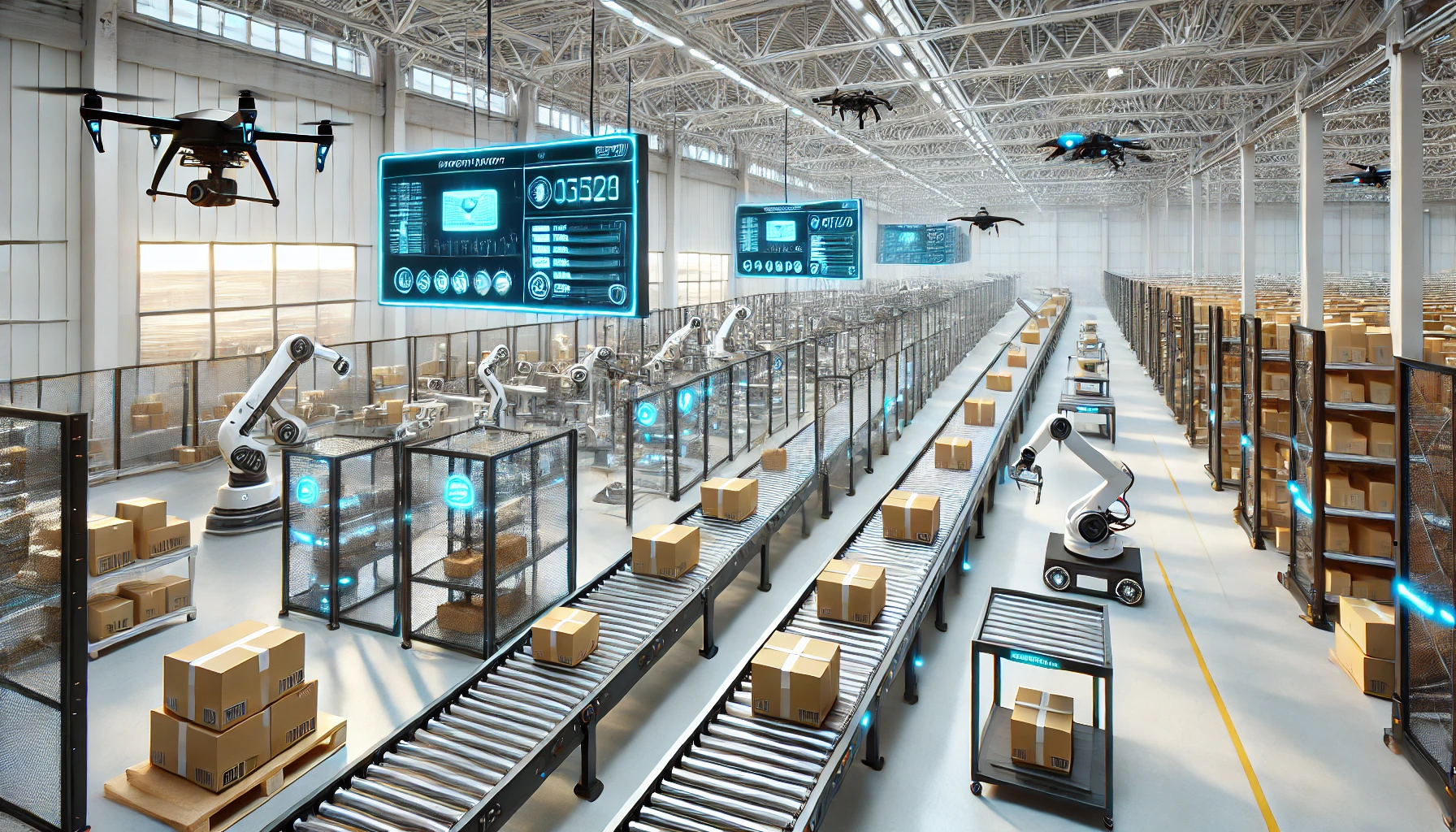

Supply chain data analysis allows us to more easily make decisions that consider various factors, such as inventory levels, product demands, incoming inventory, buying patterns, economic forecasts, and consumer trends. In fact, this data can even be fed into a machine learning system to do the number crunching for us. With all the statistics and forecasts in hand, you are suddenly in a far better position to manage inventory to meet fluctuating customer demand.

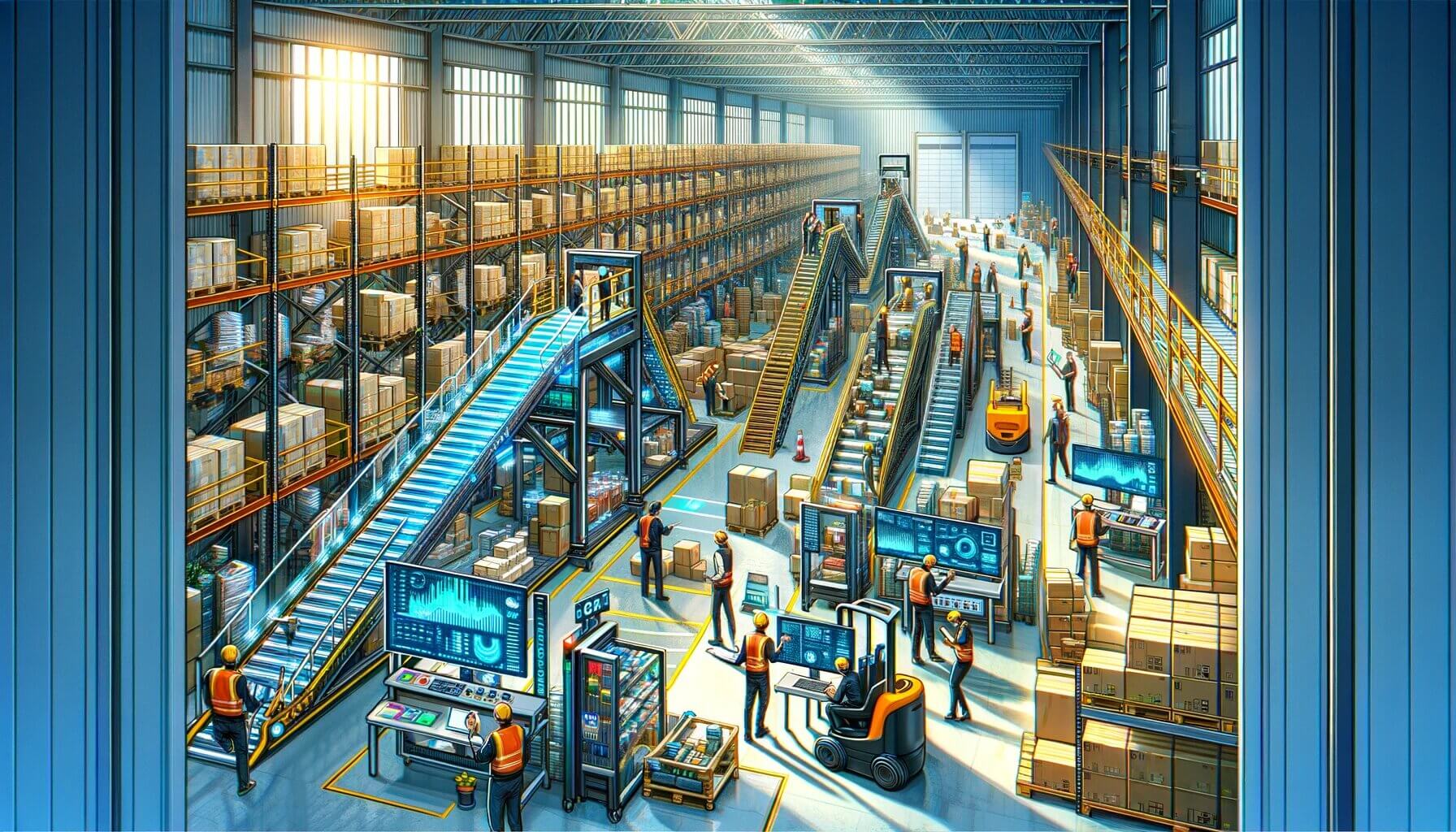

Reducing Errors in the Warehouse

What’s true of business in general is that the more visibility you have of a process or procedure, the easier it is to improve it, and this is also true for warehouses. Again, machine learning models have been used successfully to reduce error rates. These models gather data regarding cycle count tasks and product information, location and transactions. The model (or you, if you prefer!) can study this data to identify causes of error, and may even be able to predict which locations these errors are likely to crop up in.

With this information in hand, meaningful changes can be made to the processes that are leading to these errors, resulting in an increase in the accuracy of the cycle count; products will always be available whenever the customer will want them.

Greener Transportation

Using the US as an example, we can see how data can even assist you in making sure your operations meet standards and boost supply chain sustainability and efficiency. EPA’s SmartWay program can be used to help managers achieve this efficiency. Carriers can be scored by emissions and environmental impact, allowing for companies to select the most efficient carriers, transportation methods, equipment, and operational strategies. Predictive scenarios can be run by software for customers to demonstrate how much money and emissions they could save by transitioning to a SmartWay-rated carrier. As an extra, you can track the performance of said decision over time, and make a decision (or stick with one) based off of that data!

End-to-End Supply Chain Visibility

Probably the most appealing and immediate impact of data is a massive boost to supply chain visibility. It is possible to have all your demands and analytics in a single platform. Using a digital logistics marketplace would enable tracking and storage of data, operational reporting, enhanced and accurate customer service, business analytics and more.

Having such a holistic view of your operations, including warehouse-level statuses, allows for the identification of insights that can push your business towards constant improvement, refinement, and, ultimately, market advantage.

Data is a critical part of the supply chain, and can be used to improve any point in the chain. Whether it be procurement, the logistics, or last-mile deliveries, there is absolutely no aspect that would not benefit from improved analytics and visibility.