Artificial Intelligence (AI) and data are revolutionizing the business world. They’re helping companies automate, perform better, cut costs, and handle risks more efficiently.

One of the biggest impacts AI can have is on transportation, which is crucial but complex for businesses.

The supply chain, which manages how products move from creation to the customer, is a key area where AI can make a huge difference.

As the world gets more connected, supply chains get more complicated. AI can simplify these complexities, making supply chains run smoother.

AI has the potential to help organizations address these complexities and optimize their supply chains more effectively.

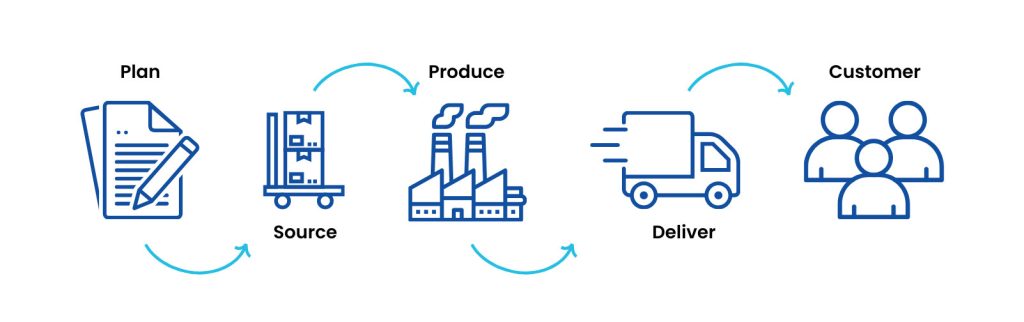

Understanding Supply Chain Network Design and Management

Supply chain management (SCM) involves overseeing a company’s supply chain network and all its activities.

It’s all about coordinating and controlling the journey of a product from start to finish. A good supply chain design is vital for business strategy.

Efficient SCM is crucial for a profitable business. It’s all about managing resources well and adapting to market changes.

By keeping track of inventory and ensuring timely delivery, companies can stay competitive with available and affordable products.

Building an Effective Supply Chain Network Design

Today, companies must quickly adapt to supply chain disruptions. They’re focusing on agile operations to handle changes in demand and shipping costs.

The uncertain market makes it essential for companies to rethink their supply chain design. They should focus on being proactive, not just reactive.

No matter the technology level, working with logistics experts is important. They help design a supply chain that meets specific business needs.

A typical design process involves setting goals, collecting data, modeling the network, and analyzing results. However, data is often messy or incomplete.

Traditional tools struggle with this, but AI-powered tools can handle imperfect data better, making for a more adaptable design.

When designing a supply chain network, using messy or incomplete data means starting off on the wrong foot. It’s like trying to build a house on shaky ground – you can’t make reliable improvements.

This is why most companies are very careful about the data they use, making sure it’s precise and detailed. However, this approach has its own issue: it creates a rigid starting point. Think of it as being stuck with a map that can’t be changed, making it hard to plan for unexpected situations or new challenges.

This is where AI comes in as a game changer. Tools equipped with AI can work magic with less-than-perfect data. They’re like having a smart assistant who can take a rough sketch and turn it into a versatile map, one that’s adaptable and ready for whatever comes its way.

This flexibility is crucial for modern supply chains, as it allows for more creative and effective solutions to the ever-changing challenges they face.

The Role of AI in Supply Chain Management

The impact of AI on supply chain management is profound and transformative. AI technologies enable more efficient and accurate forecasting, inventory management, and delivery processes.

They provide predictive analytics for anticipating market demands, optimize routes for quicker and cost-effective shipping, and enhance real-time tracking of goods. AI’s role in supply chain management leads to reduced operational costs, improved customer satisfaction, and a more agile response to market changes.

This technological integration marks a significant shift towards more data-driven, automated, and customer-centric supply chain operations.

AI can track environmental factors like weather, helping with decisions on shipping routes and fuel use. Companies like UPS are already using AI to update shipping routes for efficiency.

AI in Action: Autonomous Vehicles and Warehouse Management

In transportation, AI is behind the development of self-driving vehicles and smart route planning. For example, AI-driven vehicles can adjust routes on the go.

Walmart’s AI Journey: Walmart has set a benchmark in AI implementation in warehouse management. Their AI system analyzes sales data to predict stock requirements, ensuring optimal product availability.

This AI-powered approach is pivotal in delivering a seamless and satisfying shopping experience, especially during the holiday season. By leveraging historical data and predictive analytics, Walmart strategically places items across distribution centers and stores, optimizing the shopping experience.

These advancements in inventory management, combined with investments in their supply chain, ensure efficient delivery of items and an easy shopping experience for customers.

The AI/ML models used by Walmart offer deep insights and have been integrated to complement the use of historical data, enhancing the flow of items through the supply chain.

DHL’s AI-Powered Logistics: DHL employs AI-powered logistics to significantly enhance its delivery services. Through AI, they have achieved up to 95% certainty in predicting shipment volumes, which aids in precise route planning. This optimization allows for more efficient courier routes, with the AI-powered software from Wise Systems reordering routes with up to 120 stops in seconds, based on various parameters. The result is a smarter, faster delivery process with reduced fuel waste. This technological integration exemplifies DHL’s commitment to improving operational efficiency and customer satisfaction in the global logistics landscape

Integration with Other Technologies

AI is not a standalone solution; its true potential is unlocked when combined with technologies like IoT, blockchain, and cloud computing.

For instance, IoT devices provide real-time data that AI systems analyze for predictive maintenance in logistics vehicles.

Blockchain, on the other hand, offers a secure and transparent way to track products through the supply chain.

Future Predictions

The future of AI in supply chain management is poised for transformative changes. Emerging technologies like quantum computing could further enhance AI’s capabilities in data processing and decision-making.

Additionally, the growing emphasis on sustainable logistics practices may see AI playing a crucial role in optimizing routes for lower emissions.

Ethical Considerations and AI

As AI reshapes supply chains, it also raises ethical concerns such as data privacy and workforce displacement. Companies must address these issues transparently, ensuring responsible AI use that benefits all stakeholders.

AI systems take on high-stakes decisions in supply chain management, it’s essential to mitigate biases and uphold ethical standards. The UNESCO framework suggests core values for AI development, emphasizing human rights, diversity, inclusiveness, and environmental protection.

Companies are encouraged to conduct bias audits, use transparent AI models, and ensure human oversight for accountability and ethical judgment. Third-party regulation is also seen as crucial, as well as a cultural shift towards using AI to augment rather than replace human roles.

Data privacy is another significant concern, as supply chain and procurement divisions handle sensitive data, making them targets for cyber-criminals. Compliance with data privacy regulations like GDPR is mandatory, and as AI technology evolves, there’s a need for more robust frameworks around automated decisions and data bias.

The challenge is to respect individual privacy while harnessing the benefits of AI. The integration of AI in supply chains offers many opportunities, but it also requires a balanced approach to address ethical and privacy implications. This requires collective wisdom and ethical vigilance.

Global Market Analysis

The adoption of AI in supply chains varies across regions. In North America, AI integration is driven by the need for efficiency and competitiveness. In contrast, European companies focus more on sustainability and ethical AI practices.

Challenges and Solutions

Implementing AI in supply chains is not without challenges. Data quality and integration with existing systems are significant hurdles. Solutions like continuous data auditing and investing in scalable AI platforms can address these issues.

Current Trends and Statistics

- Improvement in Efficiency: Businesses have seen an improvement in their supply chain efficiency by up to 40% by employing AI in their supply chain management processes.

- Market Growth: The AI in the supply chain market is expected to reach $10 billion by 2025, indicating a significant investment and growth in this area.

- Impact on Logistics, Inventory, and Service Levels: Early adopters of AI-enabled supply chain management have reported improvements in logistics costs by 15 percent, inventory levels by 35 percent, and service levels by 65 percent, compared with their slower-moving competitors.

Conclusion

AI’s potential to transform the shipping and supply chain industries is undeniable, as it is one of the top trends set to transform the industry. It’s changing how companies predict demand, plan shipping schedules, and manage inventory. Supply chain leaders have been using technology for a long time, and now they’re figuring out how best to incorporate AI and large language models into their tools. This integration marks a new era in efficient and responsive supply chain management.

Wow, this blog is a real eye-opener! The insights into how AI is revolutionizing supply chain management are incredibly informative. Embracing AI is essential to stay competitive and adapt to the evolving logistics landscape.

Looking forward to more updates and learning how AI can further transform the industry!