You must optimize logistics operations to gain a competitive advantage and expand your business. Optimizing your logistics operations not only means making the process more convenient for your customers but can also mean less cost and more sales. Logistics operations are an essential part of running a business. Many of the decisions made within your organization are based on logistics, including organizing the correct delivery vehicles and their routes to ensure goods reach consumers on time. Managing these operations helps you minimize losses and maximize profits, allowing you to expand your business.

Routine Building

The first step to achieving maximum efficiency in anything is to build a routine. Planning activities helps significantly improve productivity and efficiency. It also allows you to deal with issues as they arise, reducing unnecessary stress. Just like that in logistics or any business, one should first plan to fix their routine and know what works best for their company, thus allowing them to keep growing.

Organizing and Management

It is important to keep tools in their specified locations to maintain a high level of service. Proper management allows for efficient workflow and will ultimately result in higher profits.

For example, chefs that have all the ingredients organized and ready to be used when needed will prepare food quicker; this means that customers will receive their food quicker and hotter, increasing their chances of returning. Precisely in that manner, you should organize your logistics processes to reduce error and get the same result for returning customers.

Keep it Simple

Keep everything visible so that it can be easily identified. Try to provide your employees and customers with as much as you can so they have as little to do as possible because they will mess it up if it’s more than what they can handle, which results in your loss in the end.

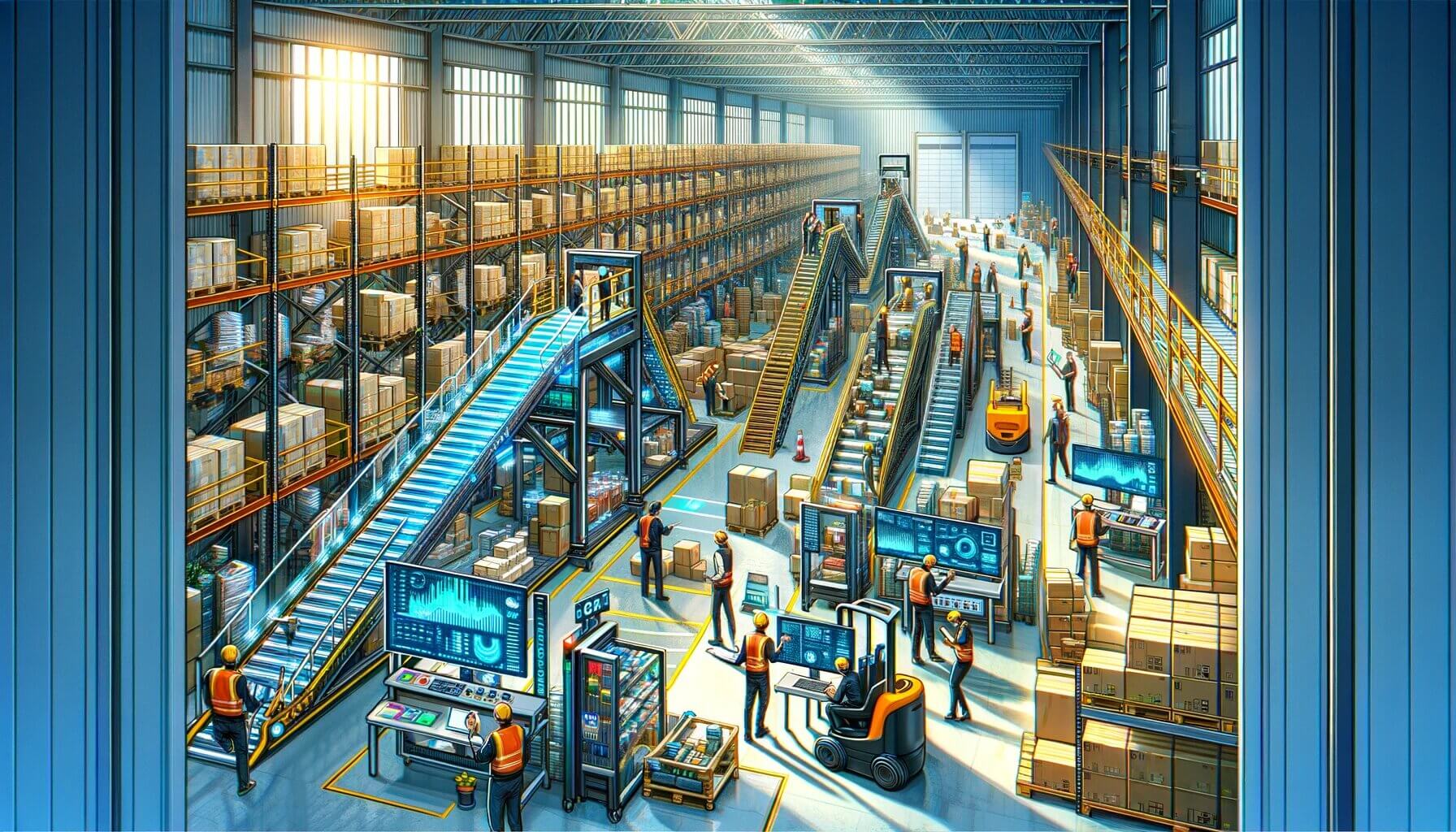

You can optimize your warehouse to make your logistics processes easier. You can do that by making minor changes to your warehouse that won’t drain you of money and instead provide you with a quicker, more cost-efficient way to make your processes faster. A numbering system for your shelves can help do this; Storage location AA3 would be the far left corner and the third level down from the top shelf. For greater efficiency, identify and label all items within your warehouse with bold-font labels that are easily readable; this will significantly reduce the wasted time that can be better utilized in making your customers happy.

Employee Management

Your employees are your team and a considerable part of your company. They make it possible for you to achieve your dream business; for them to feel that way, you need to help them feel involved in the industry and respect and acknowledge them. One way to do this is by awarding an employee of the month prize; This boosts productivity and makes them want to work hard to win the reward. Give your employees incentives and room to grow while closely managing them during the first few months on the job. Time and money spent on quality employees and retaining your workforce are never wasted. Loyal, Hardworking employees are the key to success.

Bench Marking and Best Practices

Another helpful tool is benchmarking. Benchmarking compares your business’s performance to the competition’s or the market as a whole. Benchmarks include on-time shipping, order picking accuracy, local utilization, annual workforce turnover, on-time ready-to-ship, peak truck capacity used, inventory count, and dock-to-stock cycle time.

Companies must follow certain best practices to keep their businesses running smoothly. One company that found a unique way to prevent a problem with its drivers’ keys is United Parcel Service (UPS). The UPS drivers were frequently misplacing their keys, which caused delays and other issues. The company decided to adopt the best practice of having the drivers place their keys on their pinky fingers so there would be no more lost keys. This simple change in procedure eliminated a costly problem for the company.

We can reduce the time taken up by logistics processes by making changes to the layout of our warehouse; making the distance between the pickup and truck loading area shorter translates to 100+ hours saved over the long run. We can also optimize truck unloading, storing, and loading by reducing the width of the aisles and adding more storage space without affecting efficiency.

Make use of a 3rd Party Logistics Provider.

Optimizing your logistics operations can be quite challenging and costly. It does not always make sense to have your own logistics services as they cost a lot and are extremely difficult to manage. Hiring a 3PL removes the migraines from your logistical issues and lets you focus on producing quality products and high sales. Wahyd Logistics has been providing its services all over Pakistan with more than 50,000 registered trucks and over 100,000+ completed orders. Our customers choose Wahyd for its reliability, efficiency, and customer support service. Are you fed up due to daily the difficulties faced by your logistical sector? If so, you should book a truck online with us today!

Build a routine and find any areas to improve. Spending time in the warehouse will allow you to micro-manage every problem that is faced by your business in the logistical sector. No change is too small; make sure to leave nothing out.

You may also be interested in:

Article: How to maximize the efficiency of your inbound logistics operations.

Article: How Online Logistics Marketplaces Will Help The Industry.